Remediation of Willem II Domanial Mine shaft

The remediation of shaft Willem II started in October 2022. Based on research commissioned by the Ministry of Economic Affairs, published in December 2016, it was decided to take a number of measures regionally to reduce the likelihood of potential impacts from past mining.

As you may know, mining took place in Limburg until the 1970s. The effects of that can still be felt in the soil of our province today. This does not pose any immediate problems, but it is something we should be aware of in the region.

One of the questions investigated concerns whether the mine shafts (vertical accesses between ground level and places in the subsurface where coal was mined) were left stable into the future when the mines closed in 1969-1974. The study concludes that there are no immediate safety risks. To prevent possible longer-term consequences, the minister has made funds available to perform additional work at a number of shafts to ensure that the shafts will not continue to cause problems in the future.

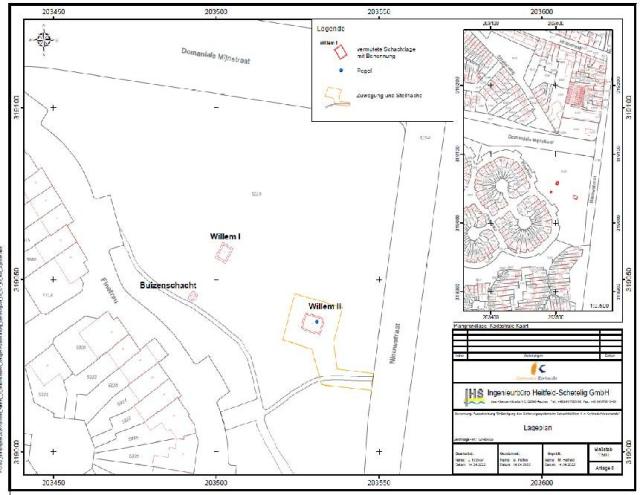

The Map below shows the locations of the three shafts of the Domanial Mine that stood on this site.

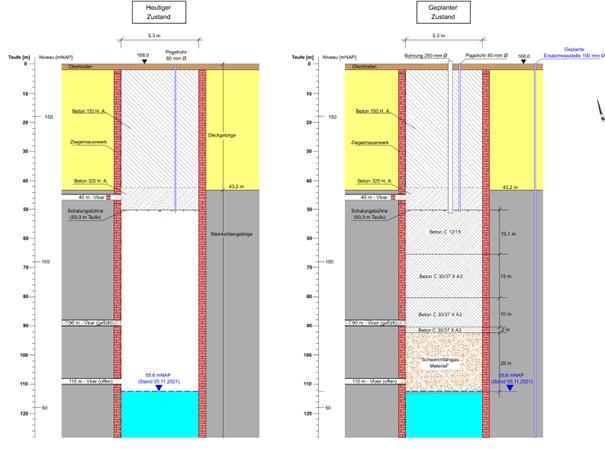

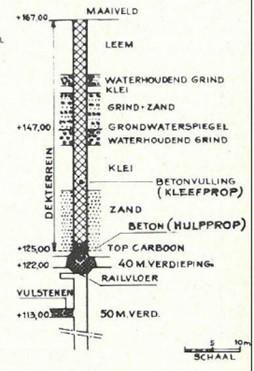

When the mine was closed, the Willem II shaft was fitted with a concrete prop that enters the shaft from ground level some 50m deep.

In order to keep this prop and the shaft stable into the future, it is necessary to increase the length of the prop.

To carry out this work, an expert German firm (Daldrup & Söhne AG) was hired to perform this kind of special work. The work involves drilling a fill hole through the existing concrete plug, applying a floating support layer (float layer) to the mine water in the shaft and then filling the hollow space of the shaft with concrete from the support layer to the bottom of the existing concrete plug.

Work will begin Oct. 26 and is expected to last until March 2023. The grassy area will be partially occupied as a work site during the work.

Work will take place on weekdays between 7 a.m. and 6 p.m. Nuisance from vibrations is not expected. Noise from the construction site cannot be ruled out during works. Materials will be supplied from Nieuwstraat. The exact construction site layout is not yet available.

Construction site

The layout of the construction site is shown in the picture below.

Duration of work

Work site layout began in October 2022. Currently, the work is expected to be completed around March 2023.

Tube shaft and Willem I shaft

If the work on shaft Willem II proceeds successfully, the two remaining shafts may be remediated subsequently.

Information on remediation

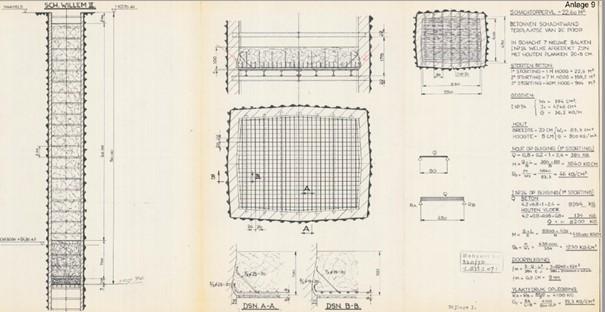

To know how the shaft was remediated around 1970, archives were searched for available records. Enough documents about the shafts of the Domaniale Mine were found in archives to give an idea about this. As an example some pictures about shaft Willem II. The shaft has a depth of 804 meters and dimensions of 5.5 by 4.3 meters.

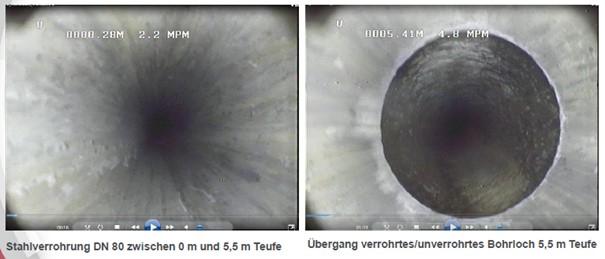

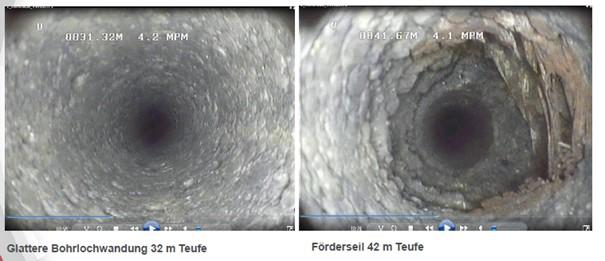

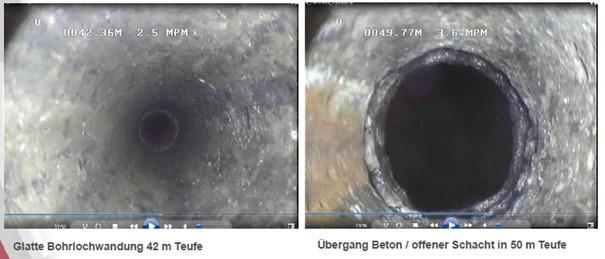

To know if the shaft was actually remediated as stated in the records, the shaft was inspected with a camera in April 2019. In the concrete plug is a drilled hole that has been used for years to gauge the mine water level in the shaft. This hole is large enough to lower a special camera down through the shaft. Some photos of the inspection:

For the first 5.5m from ground level, the camera passes through a steel tube. After 5.5m, the camera enters the concrete borehole. To be seen is not yet the open shaft itself, the camera shows the borehole.

Below right, a piece of the elevator cable can be seen in the borehole. This was encased in concrete at the time the shaft was rehabilitated.

At 50 meters below ground level, the borehole emerges into the unfilled shaft.

It can be seen that the original elevator car guides are still intact.

At 120m below ground level, the camera encountered mine water(situation 2019, meanwhile the mine water has risen to about 110m below ground level). The light from the camera reflected off the mine water and caused the "white spot."

The inspection shows that the shaft is intact and no unexpected abnormalities were seen.

The work being carried out now aims to increase length of the concrete prop by about 42 meters. It is a technical point and without going deeply into it, extending the prop is necessary to achieve sufficient contact between the prop and the shaft wall. This is because the prop hangs in the shaft based on friction between the prop and the shaft wall. In the present state of the art, the length of the existing concrete prop is too short to ensure that the shaft does not have to worry about it in the future. To achieve this, a new plug is glued to the old plug. The resulting total length of the plug ensures that the shaft does not require any further attention in terms of long-term stability.

To extend the concrete plug, a floating material is first brought onto the mine water standing in the shaft. This is necessary because otherwise the concrete to be filled will immediately disappear to the bottom of the shaft. A thin layer of special concrete is then applied to the floating material and allowed to harden. Then another thin layer is applied and allowed to harden. And so on until a load-bearing layer is formed on which further concrete can be applied until the new prop reaches the bottom of the old prop to form a single prop.

Work at the construction site consists of landscaping the construction site, making a fill opening through the existing concrete plug and filling the shaft with special concrete on the floating layer. A new monitoring well will be installed in the immediate vicinity of the shaft to monitor the mine water level.

The picture below shows the current condition on the left and the post-work condition on the right.